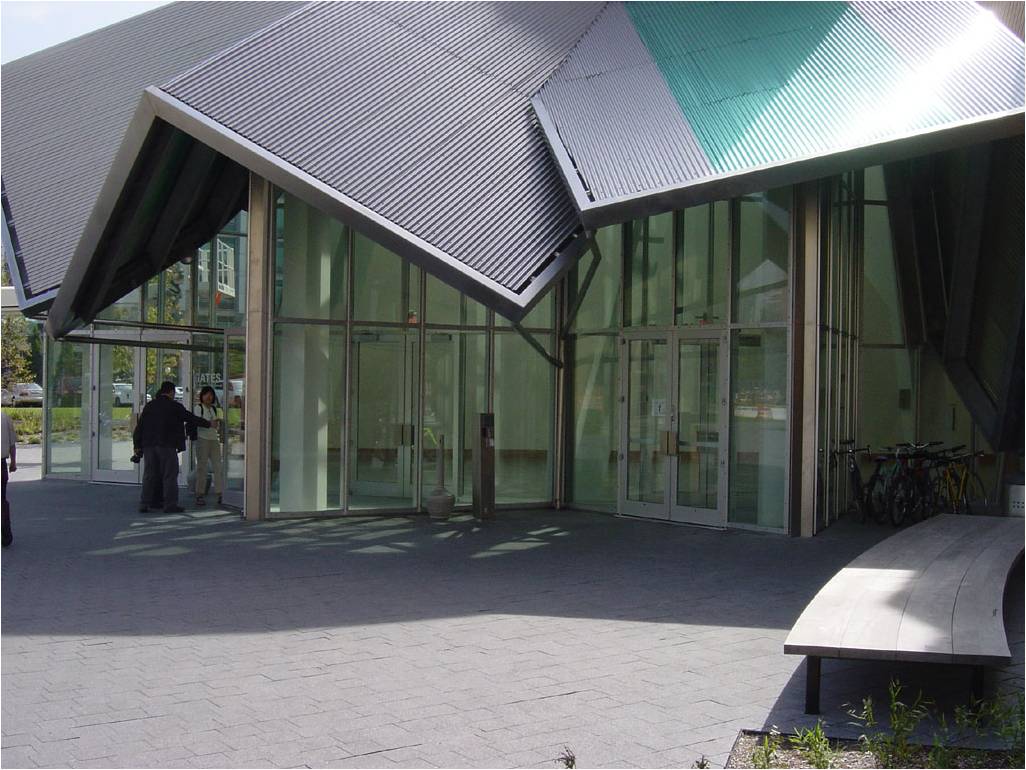

Seen from a distance a recent Gehry building may look like a sculpture. But when approaching that Gehry building, any Gehry building, from the Guggenheim Museum in Bilbao to the Stata Center in Boston, the building becomes uncomfortably more and more traditional. Finally when entering the building via the entrance there is not much special about it. You enter through a regular mass produced facade, through regular doors, built up with regular profiles, be it in the deconstructivist way brutally cut off at varying angles. Decon as usual, nothing nonstandard about it. I appreciate Gehry Technologies [GT] for their great Digital Project [DP] software, but even Jim Glymph of GT told me back in 1998 that he was admiring the awesome achievements concerning the design and execution of the Saltwater Pavilion at Neeltje Jans. DP was created to rebuild Gehry´s wrinkled and distorted silver paper models into something manageable and buildable. When the starting point of a design concept remains rooted in old concepts, the realized building will communicate in the first place the outdated concept and not the new technology, there will always be an inconvenient friction between the designer´s concept and the contractor´s execution. When there is not established a direct link between BIM and CNC the execution can be done, but it will not be consistent, it will cost an unproportionally large sum of money and is hence a threat for the truly nonstandard designers who seriously strive for the unbroken link from their generative design concept using parametric modeling in the earliest design phases to a proper CNC manufacturing procedure.