iA#1 | iA#2 | iA#3 |iA#4 | iA#5

We Robot[s]

I robot is the title of the science fiction collection of novels by Isaac Asimov, published in 1958. This is more than 60 years ago, and first recently a serious discussion on robotics has reached the international architectural discourse arena. As always, architecture is slow to pick up new paradigms. What exactly is the importance of robotic architecture? How does robotic architecture affect the art and science of building? To what extent is today’s robotics different from robotics of 60 years ago?

For today’s purposes we must replace the ‘I’ by the ‘We’. We no longer consider robots as isolated replica’s of human beings, but as members of a complex swarm, a swarm of cooperating robots. It would be even more accurate to define today’s robots as members of a swarm of the same species, interacting with many other robots of different species, including human beings and things. Things include a range of industrial products with augmented intelligence Like cell phones, furniture, building components, cars, while robots are actors in the Internet of Things. Robots are not alone, like we humans are not alone. We humans

cannot function in an isolated fashion; we exist thanks to the connectivity of our brain to other brains. They are simply different players of the same system, but cannot be seen isolated from that system. A single brain cannot exist without a multitude of other brains. Similarly, I think about robots: A single robot does not make sense; robots must be seen as actors interacting and communicating with other

actors.

Robotic swarm design

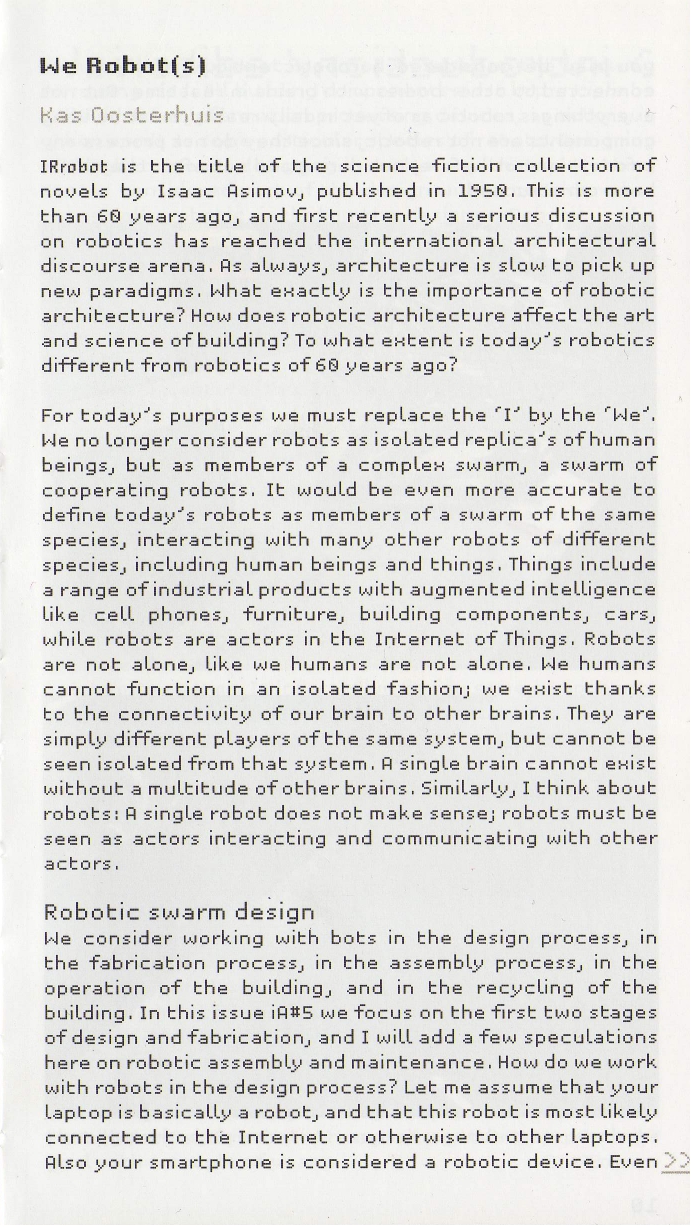

We consider working with bots in the design process, in the fabrication process, in the assembly process, in the operation of the building, and in the recycling of the building. In this issue iA#5 we focus on the first two stages of design and fabrication, and I will add a few speculations here on robotic assembly and maintenance. How do we work with robots in the design process? Let me assume that your laptop is basically a robot, and that this robot is most likely connected to the Internet or otherwise to other laptops. Also your smartphone is considered a robotic device. Even you may be considered a robotic entity since you are connected to other bodies with brains in real time. But pot everything is robotic as of yet in daily reality, most building components are not robotic, since They do not process any information not before, not during and not after they have been constructed.

Three-phase rocket

The whole enterprise at Hyperbody is based on the following intriguing idea: All building components must in principle be considered as information processing devices, as actors, in other words as some particular species of robots. Designing with robots means designing in such a way that everything that is considered part of the design will be considered as potentially robotic, including the designer. Robotic is the

default state, in case the actor is deaf, dumb and blind, this will be seen as an exception to the robotic state of each individual component. The tools that are used for robotic design are the nowadays available computing hardware and software, the innovative aspect is the intention to design from within the new paradigm of robotic swarm architecture. Thus while in daily life only a fraction of the material that surrounds us behaves robotically, in the robotic swarm design process literally every thing and every one is considered a robotic actor, interacting a streaming parametric fashion with other robotic components. It is as if you are like a three-phase rocket:

1. Parametric design. In parametric design all building components are related to their immediate neighbors and to other parameters driving their shape. Parametric design is a mandatory condition for complex geometry.

2. Interactive design. In interactive design some components can change shape and content in response to external streaming data. Prerequisite for interaction design are a variety of sensors embedded in the immediate environment that sends information to the design process.

3. Robotic design. In robotic swarm design virtually all components, both of the design subject and of the design team, are active actors that are reading, processing and transmitting data all the time to their immediate neighbors and to anyone and anything that may pick up the waves and has learned how to feed on the streaming data. A typical robotic swarm design process supports the integration of design agents, producing streaming data that feeds the evolving development of the design. Needless to say that to reach the default state of a full-blown robotic swarm design process there are still some years ahead of us, as we

are making the first exploratory steps, but are confident that Hyperbody’s robotic research agenda may reach its goal within a couple of years.

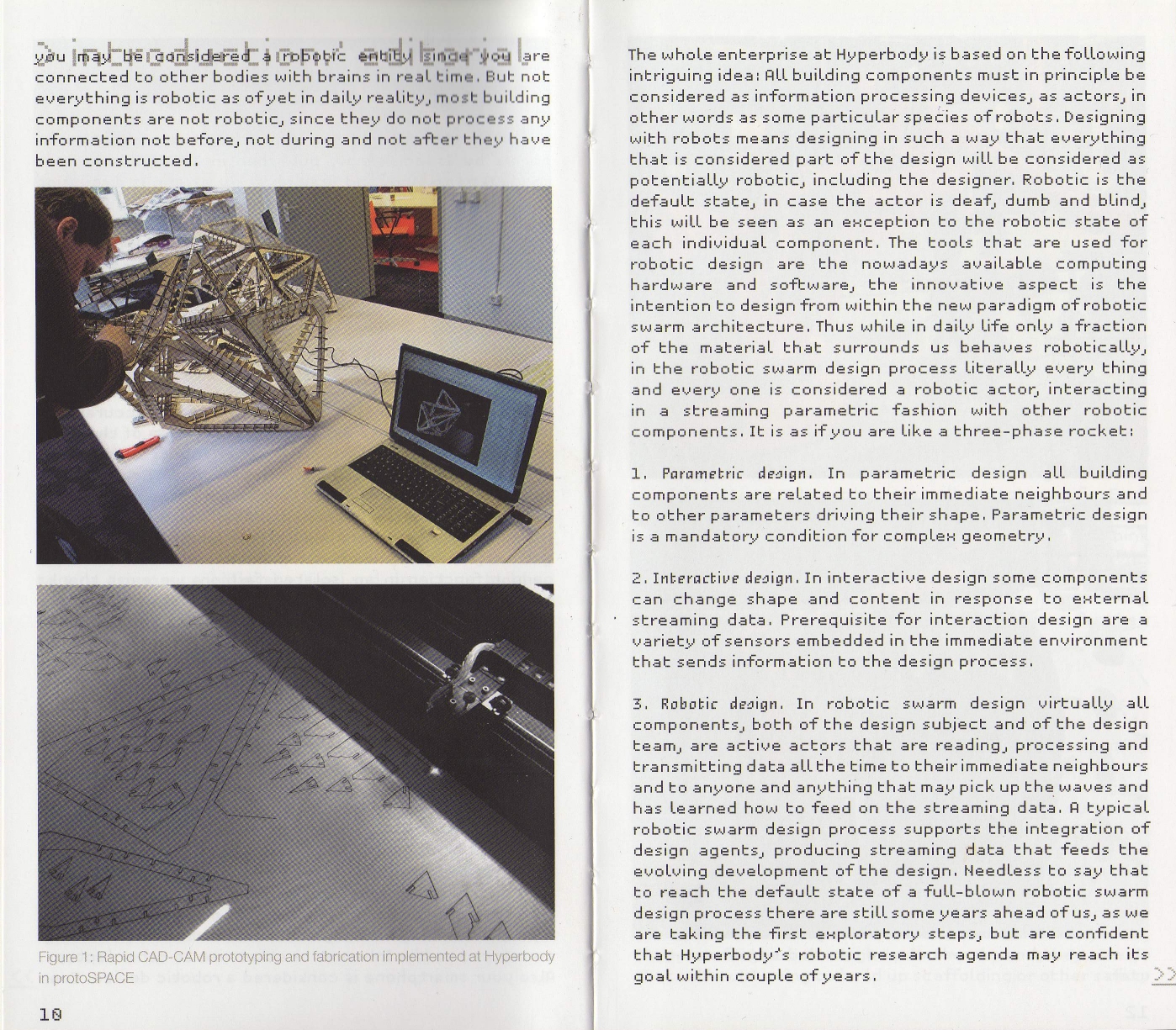

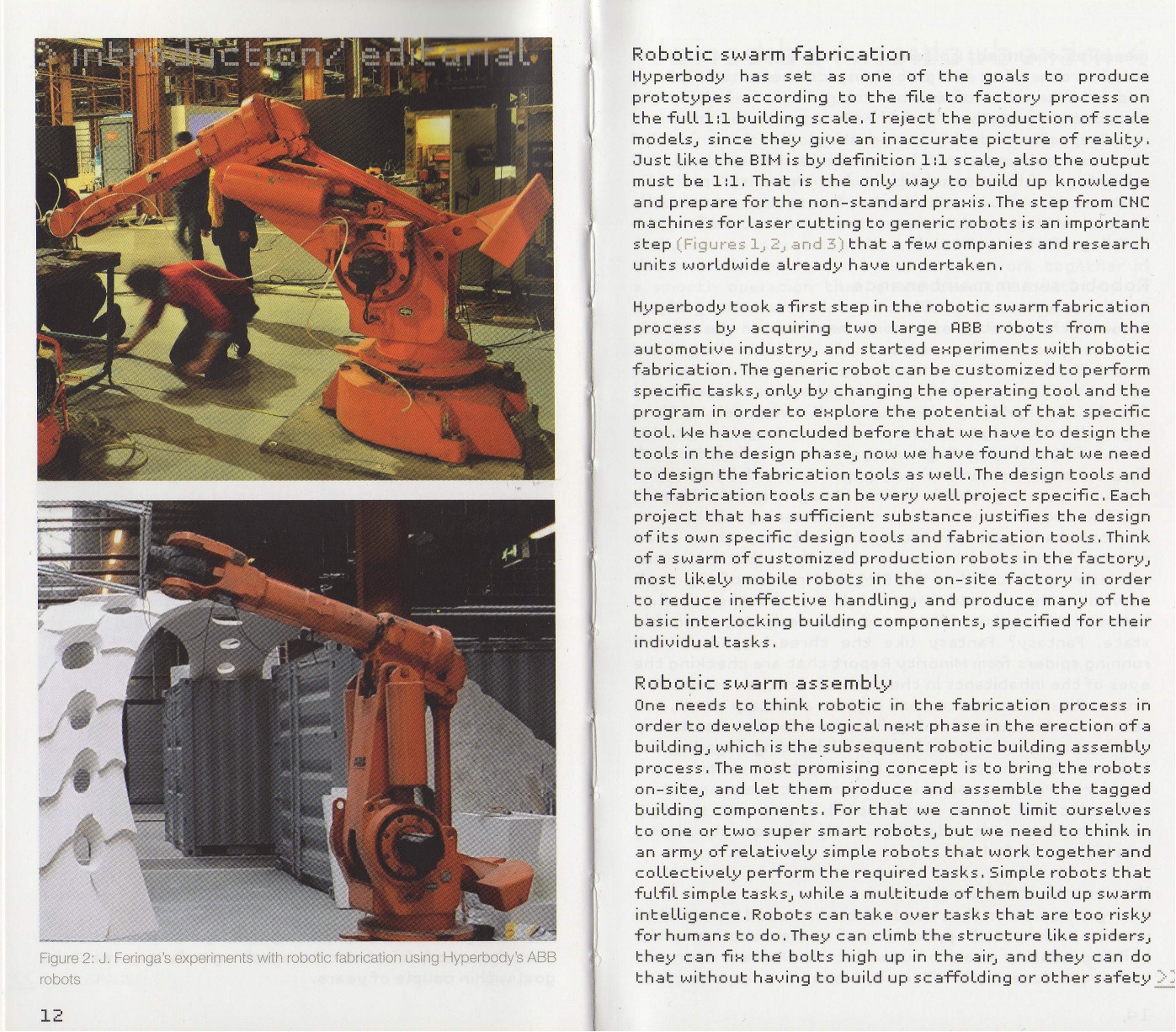

Robotic swarm fabrication

Hyperbody has set as one of the goals to produce prototypes according to the file to factory process on the full 1:1 building scale. I reject the production of scale models, since they give an inaccurate picture of reality, Just like the BIM is by definition 1:1 scale, also the output must be 1:1. That is the only way to build up knowledge and prepare for the non-standard praxis. The step from CNC machines for laser cutting to generic robots is an important step that a few companies and research units worldwide already have undertaken. Hyperbody took a first step in the robotic swarm fabrication process by acquiring two large ABB robots from the automotive industry, and started experiments with robotic

fabrication. The generic robot can be customized to perform specific tasks, only by changing the operating tool and the program in order to explore the potential of that specific tool. We have concluded before that we have to design the tools in the design phase, now we have found that we need to design the fabrication tools as well. The design tools and the fabrication tools can be very well project specific. Each project that has sufficient substance justifies the design of its own specific design tools and fabrication tools. Think of a swarm of customized production robots in the factory, most likely mobile robots in the on-site factory in order to reduce ineffective handling, and produce many of the basic interlocking building components, specified for their individual tasks.

Robotic swarm assembly

One needs to think robotic in the fabrication process in order to develop the logical next phase in the erection of a building, which is the subsequent robotic building assembly process. The most promising concept is to bring the robots on-site, and let them produce and assemble the tagged building components. For that we cannot limit ourselves to one or two super smart robots, but we need to think in an army of relatively simple robots that work together and collectively perform the required tasks. Simple robots that fulfill simple tasks, while a multitude of them build up swarm intelligence. Robots can take over tasks that are too risky for humans to do. They can climb the structure like spiders, they can fix the bolts high up in the air, and they can do that without having to build up scaffolding or other safety measures one needs to take to protect humans. Imagine one robot brings building components in place and another robot of another robot family is bolting the components together. And then imagine many of those robot species smoothly cooperating. Also keep in mind that their jobs need not be repetitive, while taking real advantage of their capabilities when they pick up and fix customized unique components. The robot needs to be

instructed to use proper parameters as extracted from the building information model.

Robotic swarm maintenance

Finally, a few words on robotic maintenance: Many of you know of the robotic lawnmower machines or the robotic vacuum cleaners that respectively populate lawns and homes. But let us think ahead, imagine an army of hundreds of façade cleaning robots, walking the three-dimensional façade like gekkos, cleaning small areas at a time, regularly returning to their base stations to get a water or soap refill, and sprawling out again over the façade. Such façades would be continuously populated with hundreds of small cooperating robotic devices. Imagine human cleaning staff to cooperate with this army of cleaning robots as to monitor the façade structure, and as to report on small failures that needs to be mended. The robotic devices are instructed to follow the BIM, and in case of any small deviation they would immediately record the conflict between the actual state and the designed, desirable state. Fantasy? Fantasy like the three-legged smooth

running spiders from Minority Report that are checking the eyes of the inhabitants in their search for the suspect Tom Cruise alias John Stanterton? No, not a fantasy at all, but rather a relevant technology required for the mandatory maintenance and inspection of tall building façades, for instance. Swarms of robots, invading both exterior and

interior territories, operating in an interactive cooperation with educated human staff, would in the end strongly reduce maintenance and subsequently failure costs leading to a higher safety level.

Human robot interaction

An urgent question that needs to be discussed here is what would a widespread application of swarm robotics in the building industry mean to human labor. We want everyone op to have a decent job after all, we want everyone to do relevant work and we do not wish to see many workers in the building industry unemployed. I became aware of this

urgency when lecturing in China and discussing with Chinese architects in August 2011, After ample consideration I believe that the solution is in the early design concept. I believe we should not refrain from advanced technical solutions like swarm robotics, but at the same time we should not automate and standardize to the extreme, but design the automation process in such a way that humans find pleasure in meaningfully interacting with the robots. Robot hands and human hands should work. together in a smooth operation that guarantees the continuity of meaningful human labor and effective robotic operation at the same time. Do not attempt to optimize a traditional building design and building processes with human robotic processes, but take advantage of their potential and create a new surprising complexity based on simple rules in such a cooperative human-robotic fashion that one is able to create a new kind of non-standard architecture that otherwise would not have been possible. That is the only justification to choose the “we robots’ road towards future building.